District heating networks, an important part of the energy transition for buildings, need a way of storing intermittent wind and solar power. But water tanks have limits: they take up a lot of space, and have a low thermal energy storage density (limited by the 100°C boiling point). Molten salts have a much higher storage density (regular table salt has a melting point of 801°C), but a melting point that is too high is not safe where ordinary people are living and working. Fintan Burke at ESCI describes research in Spain into new salts with low melting points and high energy storage densities, ideally with a heating and cooling range under 300°C. The WEDISTRICT project has developed and tested a new nitrate-based salt mixture that operates below 130°C. A tank holding just over 30 cubic metres of the salt delivered a storage capacity of 2MWh, suitable for a district heating network.

District heating networks, an important part of the energy transition for buildings, need a way of storing intermittent wind and solar power. But water tanks have limits: they take up a lot of space, and have a low thermal energy storage density (limited by the 100°C boiling point). Molten salts have a much higher storage density (regular table salt has a melting point of 801°C), but a melting point that is too high is not safe where ordinary people are living and working. Fintan Burke at ESCI describes research in Spain into new salts with low melting points and high energy storage densities, ideally with a heating and cooling range under 300°C. The WEDISTRICT project has developed and tested a new nitrate-based salt mixture that operates below 130°C. A tank holding just over 30 cubic metres of the salt delivered a storage capacity of 2MWh, suitable for a district heating network.

Storing thermal energy for district heating and cooling (DHC) continues to face the challenge of how to store this energy when it is based on an intermittent source of energy, for example solar power.

This thermal energy is usually stored through the liquid phase range of water. This restricts cooling to large, heavy single-stage absorption chillers.

Molten salts

In the past years the district heating sector has experimented with chemical salts heated and maintained beyond their melting point (known as molten salts). On the surface, these molten salts have several benefits for district heating. They usually have a massive thermal storage density; even regular table salt has a melting point of 801°C, and other engineered salts can have higher or lower melting points.

Their thermal storage density also means the volume of heat storage tanks can be reduced by up to 20 times compared to other storage technologies, lowering installation costs. Molten salt tanks can also act as boilers, avoiding the use of fossil fuel boilers to cover demand peaks. This reduces operational and capital costs as neither fuel nor extra equipment are needed anymore.

These benefits have caught the imagination of researchers. “We want to go towards greater efficiency in the storage of thermal energy and greater safety,” said Francisca Galindo Paniagua, the technical director at the Spanish chemical manufacturer Fertiberia, which develops molten salts formulations. “The new salts with low melting points and high energy storage density will be the solution to decarbonise sectors such as district heating.”

Low melting point, high energy storage density

Although there are already commercial salts used for thermal storage in solar thermal plants, commercially available nitrate salts have a safe liquid range that is unsuitable for district applications. These nitrate salts work best at temperatures above 250 °C to avoid the risk of it solidifying. Depending on when they were built, this temperature is too high to be useful for some district heating networks, which need heating and cooling ranges of 130–300 °C.

“Maintenance of systems at high temperature are more complicated than those at low temperature, for example, keeping the salt molten when there is no heat inlet,” said Galindo Paniagua. “That is why water is more suitable for district heating compared with standard salts. But new formulations at low melting point can resolve the temperature problem and safety problems related to thermal oils.”

Below 130°C

Galindo Paniagua and her colleagues in the WEDISTRICT project have developed a new nitrate-based salt mixture to operate below 130 °C. This makes it feasible to have safe thermal storage well above 100 °C for district heating.

Her company’s newly developed product called FERT-1 is a quaternary salt made from a combination of alkali and alkaline earth nitrates. The salts also have the advantage of being able to undergo many heating/cooling cycles without any noticeable change in their chemical structure.

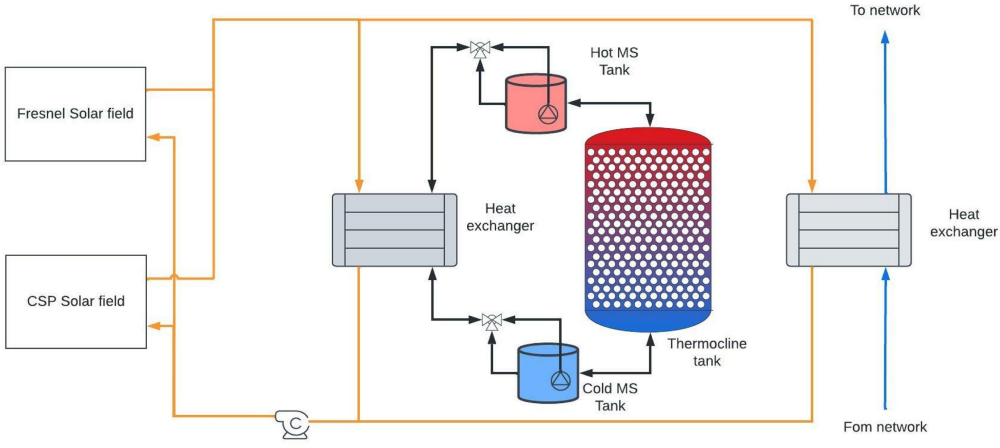

To store the molten salt, the researchers chose a thermocline tank; a single tank made of a ‘hot’ upper zone of molten salt, a lower zone of cooler molten salt, and an intermediate mixing later in the middle.

Testing the new system

To test this, the project tested the salts at “Plataforma solar de Almería,” a solar power researching centre in Andalucía, Spain. There, they have experimented with storing the thermal energy of the town’s solar energy research centre.

The molten salt tank, operating between 150 and 235 °C, was connected to concentrating solar collectors to meet demand for district heating and cooling. A biomass boiler acted as a backup for the facility.

“It was very important to evaluate thermal cycling behaviour of the salt, melting techniques, thermal behaviour in the thermocline tank, and any possible problems related to solidifications,” said Galindo Paniagua. They also tested how to best keep the salt molten when there is no heat inlet.

Their tests proved fruitful; their thermal-physical and corrosion tests showed that the carbon steel of the tank is compatible with their FERT-1 molten salt, and operates well at their target temperature of 235 °C. A tank holding just over 30 cubic metres of the salt has a capacity of 2 megawatt hours, equivalent to 4.82 hours of solar energy produced at the site.

Galindo Paniagua says that the tests at the site show that their molten salt formulation has ”demonstrated perfect behaviour for district heating applications,” and they are now working on refining the technology at another site in Spain.

***

Fintan Burke is a Writer and Editor at the European Science Communication Institute (ESCI)