Solar PV module technology moves fast, and is delivering improvements continuously. So fast that it’s no trivial matter to judge the long-term reliability of the changes. It’s a crucial issue as modules, once deployed, are expected to deliver results over lifetimes that span decades. Sara Fall and Jarett Zuboy at NREL describes a process designed to identify and address potential reliability problems quickly, before they are observed in the market. Researchers have identified eleven key technology trends within four categories that need to be analysed: module architecture, interconnects, bifacial technology, and cell technology. In their published paper, the researchers give the example of the switch from monofacial to bifacial PV module designs.

Solar PV module technology moves fast, and is delivering improvements continuously. So fast that it’s no trivial matter to judge the long-term reliability of the changes. It’s a crucial issue as modules, once deployed, are expected to deliver results over lifetimes that span decades. Sara Fall and Jarett Zuboy at NREL describes a process designed to identify and address potential reliability problems quickly, before they are observed in the market. Researchers have identified eleven key technology trends within four categories that need to be analysed: module architecture, interconnects, bifacial technology, and cell technology. In their published paper, the researchers give the example of the switch from monofacial to bifacial PV module designs.

Historically, photovoltaic (PV) modules have demonstrated high reliability, making them a dependable and growing part of global decarbonisation efforts. PV module technology also has a history of iteration and evolution over time, with potential impacts for module reliability.

With this in mind, National Renewable Energy Laboratory (NREL) researchers help to identify potential future reliability impacts in a recent review article published in IEEE Journal of Photovoltaics, “Getting Ahead of the Curve: Assessment of New Photovoltaic Module Reliability Risks Associated With Projected Technological Changes.” The article also suggests areas where additional research, standards, and testing could improve module reliability. The work was performed as part of the Durable Module Materials (DuraMAT) Consortium.

Anticipating and mitigating module reliability risks

“Anticipating and mitigating module reliability risks is central to DuraMAT’s mission,” said Teresa Barnes, one of the article’s authors and director of the DuraMAT Consortium. “In this article, we start identifying future reliability benefits and challenges from module materials and designs that haven’t been deployed in the field long enough for statistically valid failure analysis.”

Addressing concerns, capturing knowledge

The article synthesises information about crystalline silicon modules from PV market reports, interviews with PV researchers and other industry stakeholders, and peer-reviewed literature to link academic concerns with market concerns and to better capture rapidly evolving knowledge and perspectives.

“We are fortunate at NREL to have colleagues with expertise encompassing the full spectrum of module technologies and reliability research, as well as access to additional researchers and industry viewpoints through DuraMAT,” explained author Jarett Zuboy, market and policy analyst for NREL. “Our discussions with many of these experts helped shape and validate our analysis of technology trends and reliability implications, in conjunction with published sources.”

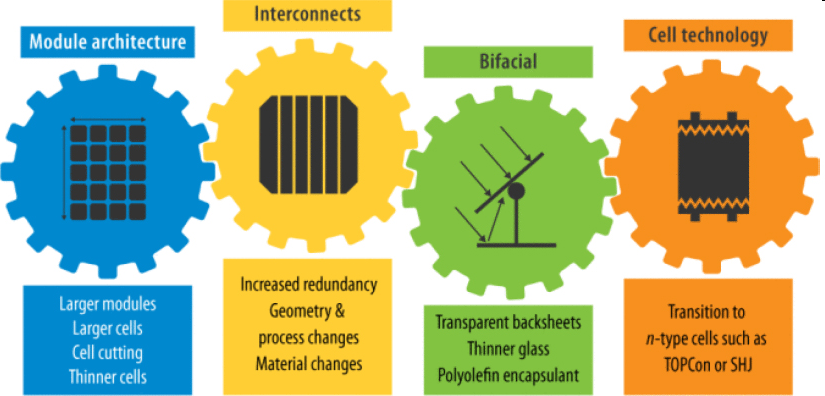

Four categories of key PV trends: Module Architecture, Interconnects, Bifacial Technology, Cell Technology

The synthesis of sources enabled the researchers to identify 11 key technology trends within four categories — module architecture, interconnects, bifacial technology, and cell technology. For each of the 11 trends (listed along the bottom of the graphic below), the authors analysed technology drivers (such as improved performance, cost, or sustainability), deployment projections, reliability implications, options for mitigating reliability risks, and the need for additional research and testing. They also explored reliability-related interactions among multiple trends.

Featured on the cover of IEEE Journal of Photovoltaics, this graphic depicts four technology categories (listed across the top) and 11 key trends in a gear motif suggesting the reliability-related interactions among multiple trends. In the module architecture category, larger modules, larger cells, cell cutting, and thinner cells; in the interconnects category, increased redundancy, geometry and process changes, and material changes; in the bifacial category, transparent backsheets, thinner glass, and polyolefin encapsulant; in the cell technology category, transition to n-type cells such as TOPCon or SHJ.

Example: the switch from monofacial to bifacial designs

As one example, the article details the ongoing switch from monofacial designs, which only convert sunlight at the front of the module, to bifacial designs, which increase electricity generation by converting light received at the back of the module as well. This trend is driving the replacement of opaque polymers with glass on the back sides of modules. It is also leading to the use of thinner glass on both the front and back of modules, as well as increased use of polyolefin-based encapsulants.

This combination of trends creates reliability considerations that are different from those associated with monofacial module designs.

“Because unique potential-induced degradation mechanisms can occur on the back side of bifacial cells and modules, there is a need to develop potential-induced degradation tests specific to this configuration,” said author Elizabeth Palmiotti, NREL materials scientist. “Reliability research on the use of thinner glass — related to both hail impacts and structural integrity — as well as the use of mixed and coextruded encapsulants and transparent polymer backsheets would also be valuable.”

Reliability: keeping pace with rapid concurrent changes

Individual PV technology changes have a range of potential effects on module reliability, from decreasing the risk of reliability problems, to having little or no impact, to increasing the risk. More important — and more complex — are the compounding effects of making multiple changes at once. For this reason, the article makes recommendations for addressing the complexity of numerous, interrelated technology trends, in addition to the specific recommendations for each technology category.

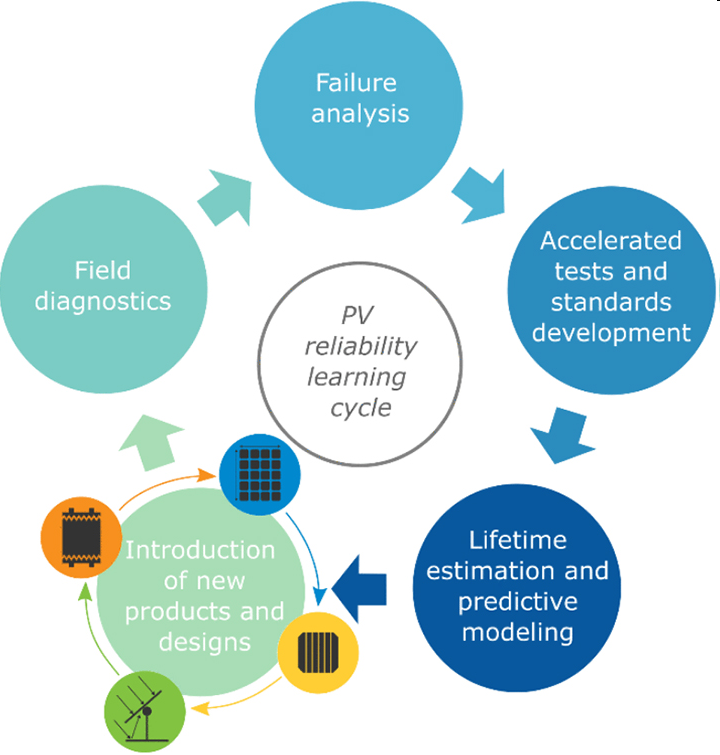

The PV reliability learning cycle enables continuous improvement to ensure module quality as rapid technological change continues.

The researchers highlight the role of the PV reliability learning cycle in keeping module quality in lockstep with technological change. The cycle begins with the introduction of new products and designs, and the remaining steps provide a holistic reliability assessment that includes field diagnostics, failure analysis, accelerated tests and standards development, and lifetime estimation and predictive modelling. The cycle starts again when previous findings are incorporated into module performance and reliability improvements through new technological changes.

Although the published article covers only crystalline silicon modules, the team is developing a follow-on article that will include thin-film technologies as well, while providing additional details on key trends affecting crystalline silicon technologies.

“The learning cycle — including the development of predictive models — helps us go beyond analysis at any given point in time to identify and address potential reliability problems quickly, before they are observed in the market,” said author Martin Springer, materials scientist at NREL. “This is what we mean by getting ahead of the curve.”

Read the full article, “Getting Ahead of the Curve: Assessment of New Photovoltaic Module Reliability Risks Associated With Projected Technological Changes,” from IEEE Journal of Photovoltaics. Contact report authors Jarett Zuboy and Teresa Barnes for more information.

***

Sara Fall is a Communications Project Manager & Writer at NREL

Jarett Zuboy is a markets and policy analyst at NREL

This article is published with permission from the National Renewable Energy Laboratory